Pasi pemamiriro ekuoma, kudzika kwakakura kwekucheka kunoshandiswa pakugadzirisa kuderedza nhamba yekupfuura uye kuvandudza chibereko chebasa rekushanda;pakupedzisa, kudzika kudiki kwekucheka kunowanzo shandiswa kuwana yepamusoro yepamusoro mhando.Inobata kurongeka kwekupedzisira machining uye kushanda zvakanaka kwechishandiso, mukuwedzera kune zvikonzero zveCNC muchina chishandiso pachayo, inofanirwawo kusanganisira inonzwisisika machining nzira marongero, kusarudzwa kwezvishandiso uye kuisirwa kwakaringana, sarudzo inonzwisisika yekucheka huwandu, hunyanzvi hwekugadzira, uye nekukurumidza. kudzora kwedimensional kurongeka.kutarisisa kwakadzama.

1. Unyanzvi hwekuronga

NC programming ndiyo inonyanya kukosha basa reNC machining.Izvo zvakanakira uye zvakaipira zveiyo workpiece machining chirongwa zvinokanganisa zvakananga yekupedzisira machining kunyatsoita uye machining kunyatsoshanda kwemuchina chishandiso.Inogona kutanga kubva kune akati wandei, sekushandisa zvine hungwaru kwezvirongwa zvemukati, kudzikisira kwekukanganisa kweCNC system, uye kushandiswa kuri nyore kwezvirongwa zvikuru uye subprograms.

1. Flexible kushandiswa kwechirongwa chikuru uye subprogram

Mukugadziriswa kwezviumbwa zvakaoma, zvinowanzogadziriswa nenzira yeimwe mold uye zvidimbu zvakawanda.Kana paine maumbirwo akati wandei paforoma, hukama huri pakati pechirongwa chikuru nechikamu chidiki hunofanira kushandiswa zviri nyore, uye subprogram inofanira kudanwa kakawanda muchirongwa chikuru kusvika kugadziridzwa kwapera.Iyo haigone chete kuve nechokwadi kuenderana kwekugadzirisa zviyero asi zvakare kuvandudza kwayo kushanda kwayo.

2. Deredza kukanganisa kunowedzera kweCNC system

Kazhinji, nzira yekuwedzera inoshandiswa kuronga workpiece, iyo inobva pane yapfuura poindi.Nenzira iyi, kuenderera mberi kwekuita kweakawanda-segment zvirongwa zvinozoburitsa imwe kukanganisa kukanganisa.Naizvozvo, edza kushandisa absolute programming kana chirongwa, kuitira kuti chikamu chega chega chepurogiramu chinobva pane workpiece.Mabviro ndiwo bhenji, kuitira kuti iko kuwedzeredza kukanganisa kweiyo CNC system kuderedzwa uye iko machining iko kuvimbiswa.

Kurongeka kweMachining kunonyanya kushandiswa kugadzira zvigadzirwa, uye kurongeka kwekugadzira uye kukanganisa kwemuchina ndiwo mazwi anoshandiswa kuongorora geometric paramita yenzvimbo yakagadzirwa.Nekudaro, iwo chaiwo paramita anowanikwa chero machining nzira haazove akanyatsojeka.Kubva pakushanda kwechikamu, chero bedzi kukanganisa kwekugadzira kuri mukati mehutano hwekushivirira hunodiwa nechikamu chekudhirowa, inofungidzirwa kuti machining accuracy anovimbiswa.

Machining accuracy inoreva iwo chaiwo geometric parameters (saizi, chimiro uye chinzvimbo) chechikamu mushure mekugadzira.Musiyano pakati pavo unonzi machining error.Saizi yekukanganisa kwemuchina inoratidza mwero weiyo machining iko.Iyo yakakura kukanganisa, kuderera kweiyo machining kurongeka, uye kudiki kukanganisa, kunowedzera kurongeka kwekugadzira.Iyi inotevera sumo pfupi kune nzira dzekuvandudza machining iko kweiyo workpieces:

1. Gadzirisa maitiro ekugadzirisa

1): Nzira yekucheka kwekuedza inogadziriswa nekucheka kwekuedza - kuyera ukuru - kugadzirisa kuwanda kwekuruma kwebanga kwechishandiso - kucheka nekucheka - edza kucheka zvakare, uye zvichingodaro kusvikira chiyero chaidiwa chasvika.Iyi nzira ine yakaderera kugadzirwa kwekuita uye inonyanya kushandiswa kune imwechete-chidimbu diki batch kugadzirwa.

2): Iyo nzira yekugadziridza inowana saizi inodiwa nekufanogadzirisa nzvimbo dzehukama dzemuchina chishandiso, gadziriso, workpiece uye chishandiso.Iyi nzira ine chibereko chepamusoro uye inonyanya kushandiswa pakugadzirwa kwehuwandu.

2. Deredza chikanganiso chemuchina

--Kutenderera kwakarurama kwekutakura kunofanira kuvandudzwa

①Sarudza yakakwirira-chaiyo rolling mabhengi

②Kushandisa yakakwirira-chaiyo yakawanda-oiri wedge ine simba rekumanikidza mabearings

③Kushandisa yakakwirira-chaiyo hydrostatic fani

--Kuvandudza huchokwadi hwezvishandiso zvine mabearings

①Kuvandudza iko iko kwekugadzira kwemabhokisi ekutsigira mabhokisi uye spindle magazini

②Kunatsiridza kurongeka kwekugadzira kwenzvimbo yekubatanidza nekubereka

③ Mema uye gadzirisa iyo radial runout renji yezvikamu zvinoenderana kuti chikanganiso chibhadhare kana kukanganisa.

--Yakafanorongera kutakura kunotenderedza

①Inogona kubvisa gaka

②Kuwedzera kuomarara

③ Homogenization yeku rolling element kukanganisa

--Iyo yekutenderera kutenderera kwechokwadi haina kuratidzwa pane workpiece

3. Deredza kukanganisa kwekutapurirana kweketani yekutumira

(1) Huwandu hwezvikamu zvekutapurirana idiki, cheni yekutapurirana ipfupi, uye kurongeka kwekufambisa kwakakwira.

(2) Kushandiswa kwekutapurirana kwedeceleration musimboti wakakosha wekuona kuti kufambiswa kwechokwadi, uye padhuze peya yekutapurirana kusvika kumagumo, idiki chiyero chekufambisa chinofanira kunge chiri.

(3) Kurongeka kwechidimbu chekupedzisira kunofanira kunge kwakakwirira kudarika kwezvimwe zvikamu zvekutumira

Chechina, kuderedza kushandiswa kwezvishandiso

(1) Chishandiso chinofanirwa kurodzwa zvakare chisati chapfeka saizi yechombo chasvika padanho rekupfeka nekukurumidza

(2) Sarudza akakosha ekucheka mafuta ekuzora azere

(3) Chishandiso chekushandisa chinofanira kusangana nezvinodiwa maitiro

5. Deredza kushushikana uye deformation yehurongwa hwekugadzirisa

(1) Kuvandudza kuoma kwehurongwa, kunyanya kuoma kwezvisungo zvisina simba muhurongwa hwekugadzirisa.

(2) Deredza mutoro uye kuchinja kwayo

6. Deredza kupisa kwekupisa kwemaitiro ekugadzirisa

(1) Deredza kugadzirwa kwekupisa kwenzvimbo yekupisa uye bvisa iyo inopisa

(2) Equilibrium tembiricha munda

(3) Gamuchira inonzwisisika muchina chishandiso chikamu chimiro uye gungano bhenji

(4) Kurumidza kuti uwane kuenzana kwekutamisa kupisa

(5) Dzora tembiricha yakapoteredza

Nomwe, kuderedza kusara kunetseka

(1) Wedzera nzira yekupisa kupisa kubvisa kushushikana kwemukati;

(2) Rongedza nenzira ine mufungo maitiro etekinoroji.

Iyo iri pamusoro ndiyo nzira yekudzikisa kukanganisa kwechishandiso chebasa, uye kurongeka kunonzwisisika kwemaitiro kunogona kunyatso kuvandudza kurongeka kweworkpiece.

Zvakawanda nezvemavara ekwakabva panodiwa kuti uwane rumwe ruzivo rweshanduro

Tumira mhinduro

Side panels

Nhoroondo

Saved

Batsira

2. Kugadzirisa kunonzwisisika kwekugadzirisa nzira

Kugadzika kunonzwisisika kwekugadzirisa nzira uye kutevedzana kwekugadzirisa hwaro hwakakosha hwekugadzirisa chirongwa chekugadzirisa workpiece.Inogona kutariswa kubva pachikamu chenzira yekugadzira uye nzira yekudyisa.

Paunenge uchiita CNC kugaya kweiyo workpiece, zvinodikanwa kusarudza yakakodzera nzira yekudyisa zvinoenderana nezvinodiwa tekinoroji zveworkpiece kuti ive nechokwadi chekucheka chaiko uye kugadzirisa kushanda kweiyo workpiece.Paunenge uchigadzira iyo yekunze contour yebasa rendege, nzira dzekucheka-mukati uye dzakachekwa dzechishandiso dzinofanirwa kurongwa.Edza kucheka mukati nekubuda uchitevedza mutsara wekuwedzera wecontour curve kudzivirira mavanga ebanga pamharadzano.Panguva imwecheteyo, mukugayo, kugaya pasi kana kumusoro kunofanirwa kusarudzwa zvinoenderana nemamiriro eiyo workpiece.

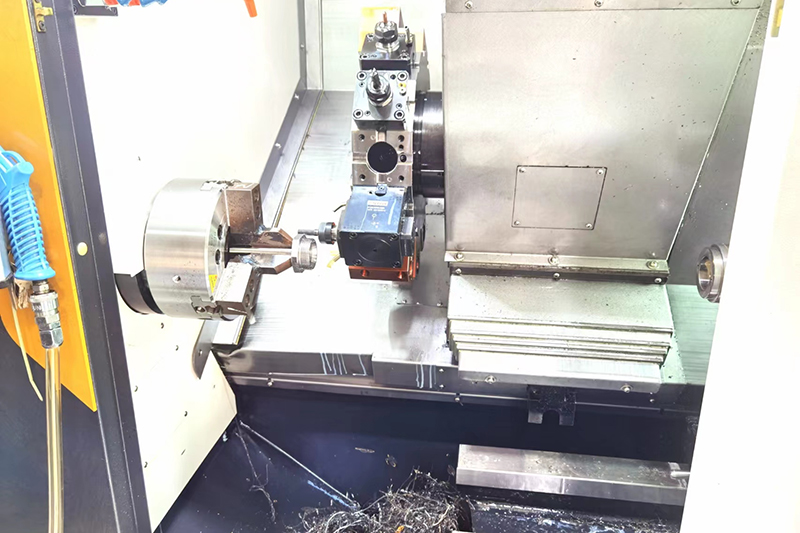

3. Kusarudzwa kwechishandiso uye kugadzirisa kwakakodzera

Ingave iri CNC machining kana yakajairwa machining, chishandiso chinoshanda zvakananga pane iyo workpiece, saka kusarudzwa kwayo uye kuisirwa ndiyo inonyanya kukosha machining echokwadi uye pamusoro pemhando yeworkpiece.Kunyanya kana workpiece ichigadziriswa paCNC machining centre, maturusi anochengetwa mumagazini yezvishandiso mberi, uye kana kugadziriswa kwatanga, haakwanisi kutsiviwa pakuda.Naizvozvo, iyo yakajairwa misimboti yekusarudzwa kwechishandiso ndeiyi: kugadzika nyore uye kugadzirisa, kusimba kwakanaka, kusimba kwepamusoro uye kurongeka kwakanyanya.

4. Chisarudzo chinonzwisisika chekucheka chiyero

Iko kutsunga kwehuwandu hwekucheka chikamu chakakosha cheCNC machining process.Saizi yaro ndiyo yakakosha paramende yekufamba kukuru uye kufambiswa kwekudya kwechishandiso chemuchina, uye ine kukosha kwakakosha pakurongeka kwemachina, kushanda kwemuchina uye kupfeka kwechishandiso kwechishandiso.Kusarudzwa kwehuwandu hwekucheka kunosanganisira kukurumidza kucheka, kumashure kwekucheka huwandu uye huwandu hwekudya.Nheyo yekutanga yekusarudza ndeye: kana iyo rigidity ichibvumira, kudzika kwakakura kwekucheka kunoshandiswa roughing kuderedza nhamba yekupfuura uye kuvandudza kubereka kweiyo workpiece;kudzika kudiki kwekucheka kunowanzo shandiswa kupedzisa kuti uwane yepamusoro yepamusoro mhando.

Nguva yekutumira: Sep-26-2022